Simple Machines STEM - Operation: Secret Lever | 5th Grade STEM Innovators

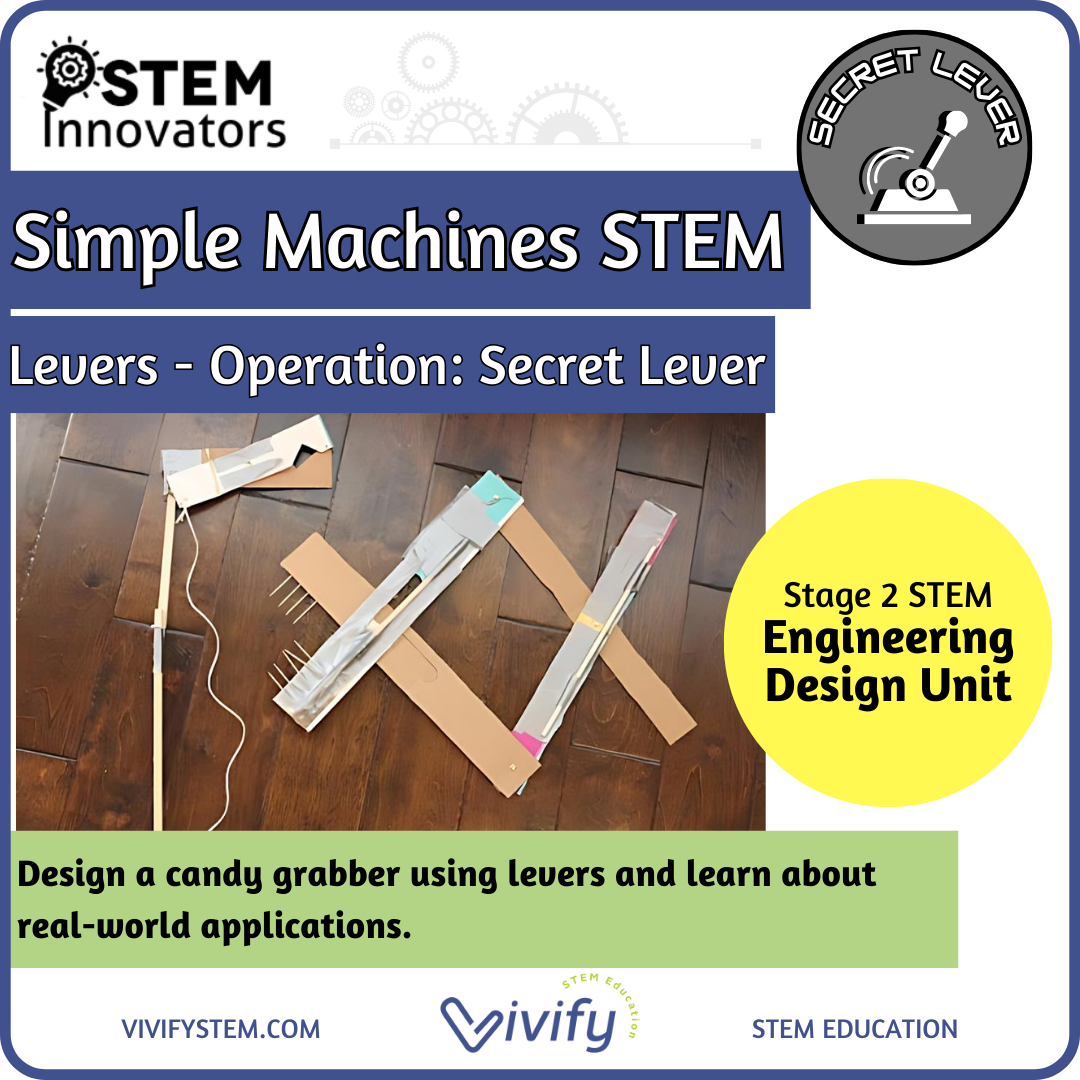

In this hands-on engineering challenge, students step into the role of inventors and problem-solvers as they design a mechanical solution to a fun (and sneaky!) problem. Blending engineering design with physical science, this unit challenges students to create a candy grabber that uses at least one lever mechanism to retrieve candy without being detected by factory workers.

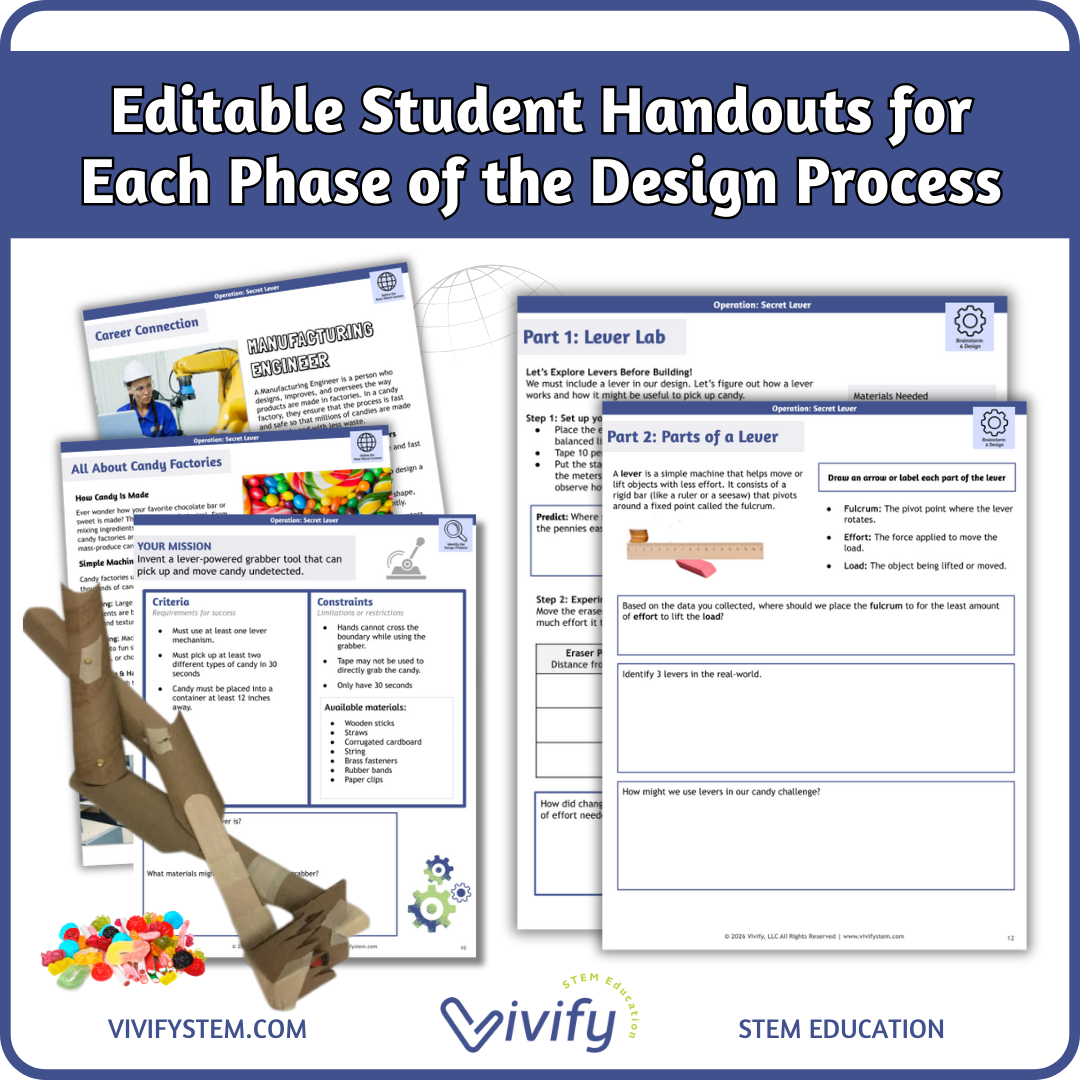

Students begin by exploring how levers work through interactive mini-labs, experimenting with different fulcrum positions and observing how these changes affect force and motion. Using what they learn, students then design, build, test, and improve their own candy grabbers. Through testing and data collection, they evaluate how well their designs function and make evidence-based improvements, just like real engineers!

Students Will Learn How to:

Understand what levers are and how they are used in everyday tools

Explain why engineers use levers to solve problems

Conduct a scientific investigation by building levers and adjusting the fulcrum

Identify which properties of levers were most important in their design

Compare their original plan with what actually happened during testing

Analyze why some designs were more successful at grabbing candy than others

Collect, record, and interpret data from their design tests.

STEM Innovators Storyline (Adaptable for Grades 3 - 5): Agents, your mission begins now. The world’s top spy agency has recruited the brightest minds for a series of top-secret operations. Your task: design and engineer cutting-edge spy gadgets to crack codes, outsmart villains, and save the day. Succeed, and you’ll rise through the ranks to become an elite STEM Innovator, trusted with the world’s most classified missions.

A Mission to Design an "Undetectable" Candy Grabber: In this unit, students will learn about common characteristics of levers and their various uses. Students will complete two mini labs with levers to spark their curiosity. They will then design and build their own candy grabber!

Engineering Learning Goals in this unit include:

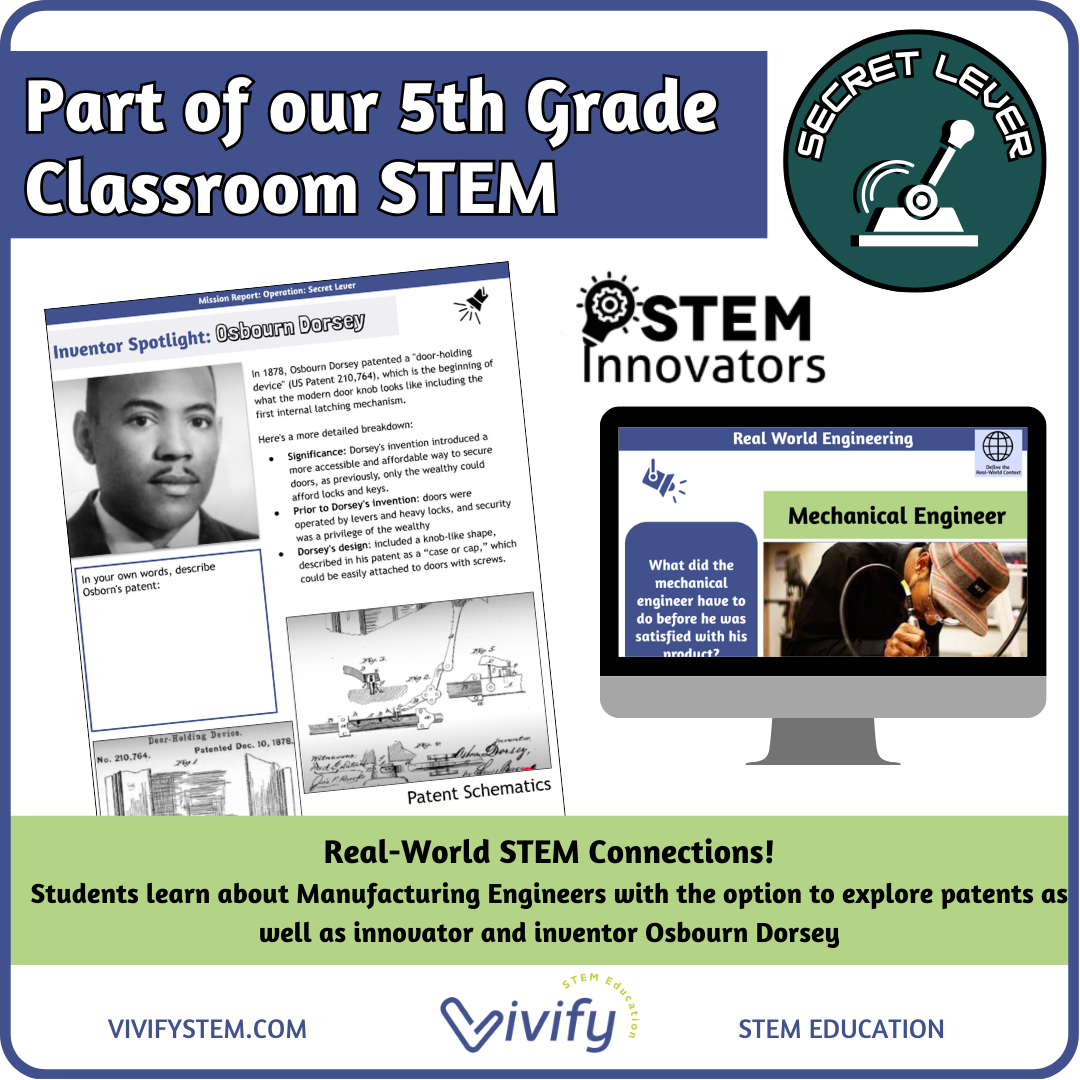

Real-World Connections: Learn that engineers use simple machines like levers to create mechanical solutions to problems. Learn about a career as a mechanical engineer as well as what a patent is and the historical significance of black innovator and inventor Osbourn Dorsey.

Making: Use a yardstick, pennies and an eraser to make a lever. Test different positions of the fulcrum to create the least amount of effort. Re-design based on testing data.

Habits of Mind: Work as a team to build a design that solves a problem. Communicate ideas and provide feedback to peers.

Science: Learn the parts of a lever, how to use a lever to make work easier, and about levers in the real world.

Technology: Learn about levers and how they are used to solve problems, how a lever works, and that levers are used in so many everyday things.

Math: Collect data of the design and use that data to make informed design changes. Multiplication, division and area of a circle and graphing.

Included in this product:

Aligned to: NGSS, TEKS, and ITEEA Standards

Complete Teacher Guide following the engineering design process

Materials list and activity suggestions

Editable teaching slides

Student handouts for each phase of the design process, including science background, STEM career connection, and more!

Two versions of student badges for completing the mission: pre-colored or a black and white option for students to color themselves to celebrate!

Recommended Supplies:

Building Materials

Wooden paint stirrers or 12” square dowel sticks

Tape (Duct works best)

Plastic straws

Single-hole punch

Corrugated cardboard (like from a cardboard box)

String

Scissors

Brass fasteners (long works best)

Rubber bands

Paper clips

Sandpaper

Toothpicks

Testing Materials

Candy variety (lollipops, candy hearts, chocolate candy, etc.)

Container (Tupperware, box, etc. to drop candy in)

2021 Science TEKS Standards Alignment (Texas)

Practices: 1A/B/D/E/F/G, 2A/B/C/D, 3A/B, 4A/B/C

Content: 3.6B, 4.7B, 5.6D, 5.7A/B